"Houston, we have a problem”.

On 13 April 1970, the world held its breath as the Apollo 13 spacecraft hurtled toward the moon. With oxygen supplies leaking into space, there was little time to make critical decisions. By adding live telemetry data from the physical spacecraft to their digital copy, Mission Control could simulate different strategies and bring the crew safely back to Earth.

The incident was a near-disaster but also a triumph of human resilience. And believe it or not: It's widely believed that the very first digital twin was used in conjunction with the Apollo 13 mission – although it wasn't called a "digital twin" at that time.

What is a digital twin?

In short, a digital twin is a virtual copy of a physical object that exists in the real world, just like NASA's physical spacecraft, and its digital model, joined together with the available live data.

Today, the technology has expanded to other industries, including construction and building management.

Even twins are different: Geometric vs. Digital

To make a digital twin, you need to have a physical object (in our case, a building) that you recreate in a 2D or 3D model. But – simply making this digital model doesn't make the data file a digital twin. What we are talking about here is a geometric twin. Remember: we're still missing NASAs "live data."

But what if you attach sensors to the building so that if something changes, the digital copy changes too? Then you're getting closer.

Let's look at an example: We create a digital model of an office building with all the rooms, doors, and technical equipment installed. To keep the twin alive and make it "smart", we install sensors in the building. The sensors pick up fluctuations in temperature and air quality in each room. It can also alert us when something happens to the power grid or ventilation system.

How to integrate

And just like that, a digital twin has been created.

What can you use it for?

As the twin develops, energy use and operations can become increasingly autonomous and self-governing.

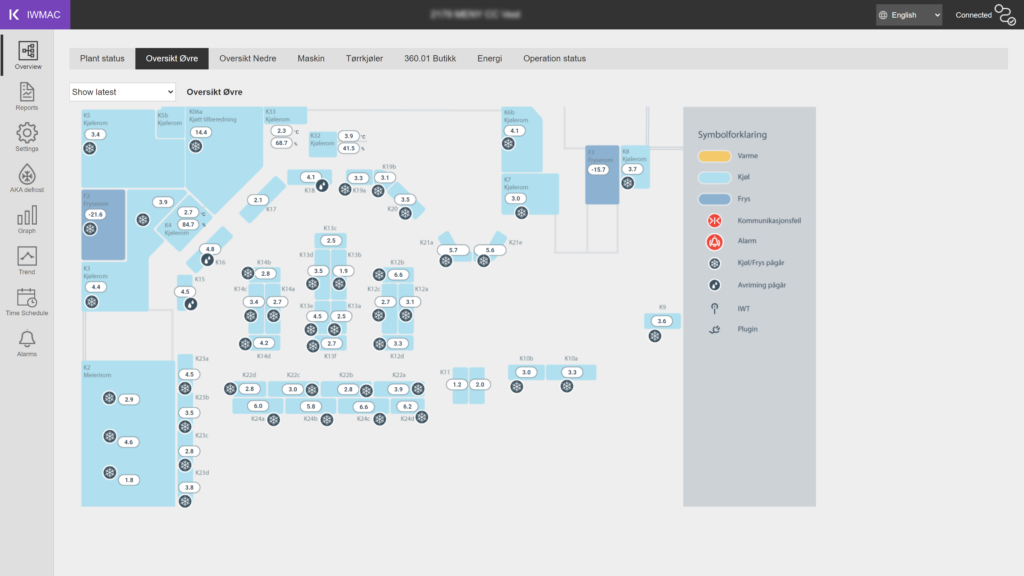

1. Monitoring and visualization

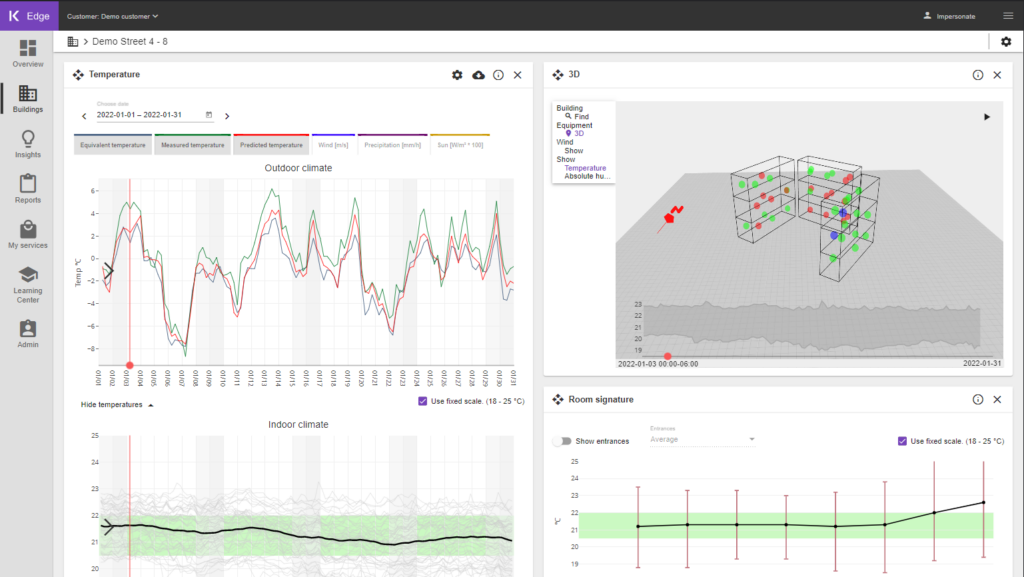

A digital twin allows you to monitor and visualize real-time data from sensors and other sources. This can include information about temperature, humidity, energy usage, and more. By visualizing this data in a 2D or 3D model of the building, you get real-time analytics and insight into how the building is used and performs.

2. Predictive maintenance

If you're spending a lot of your time doing inspections (to hopefully catch a problem) or doing firefighting by reacting when faults have already happened; there is a simpler way.

By analyzing the incoming data, the twin can predict maintenance needs before they become major issues.

3. What-if scenarios

A digital twin can simulate different scenarios, such as changes to the building's layout, external impacts, or the addition of new systems and equipment. By simulating these scenarios in the digital twin, you can make sure that the measures and changes you are implementing are for the better.

Looking to be proactive from anywhere – anytime?